Laser cutter for high-volume EGR-cooler production

PVI Hydroforming in Vansbro, Dalarna, needed a laser cutter to produce their EGR-coolers for trucks.

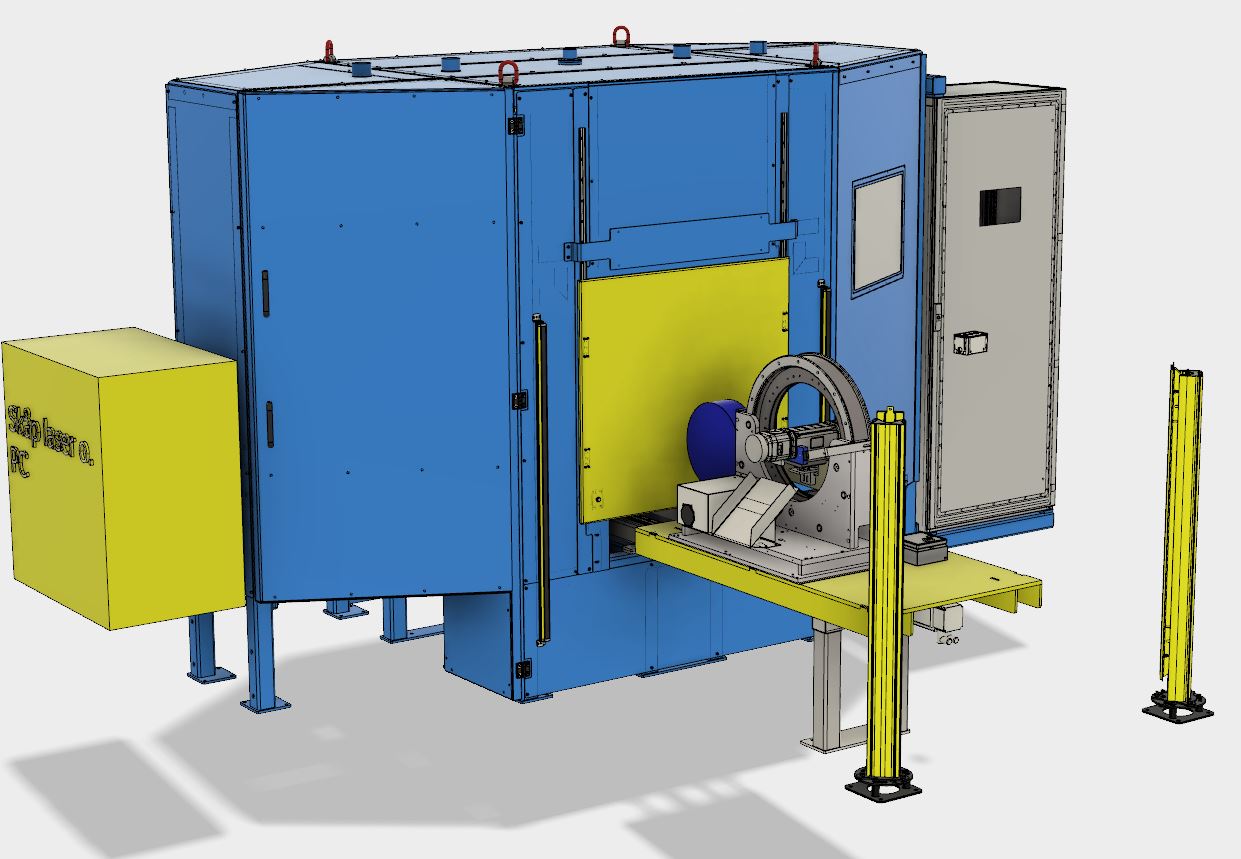

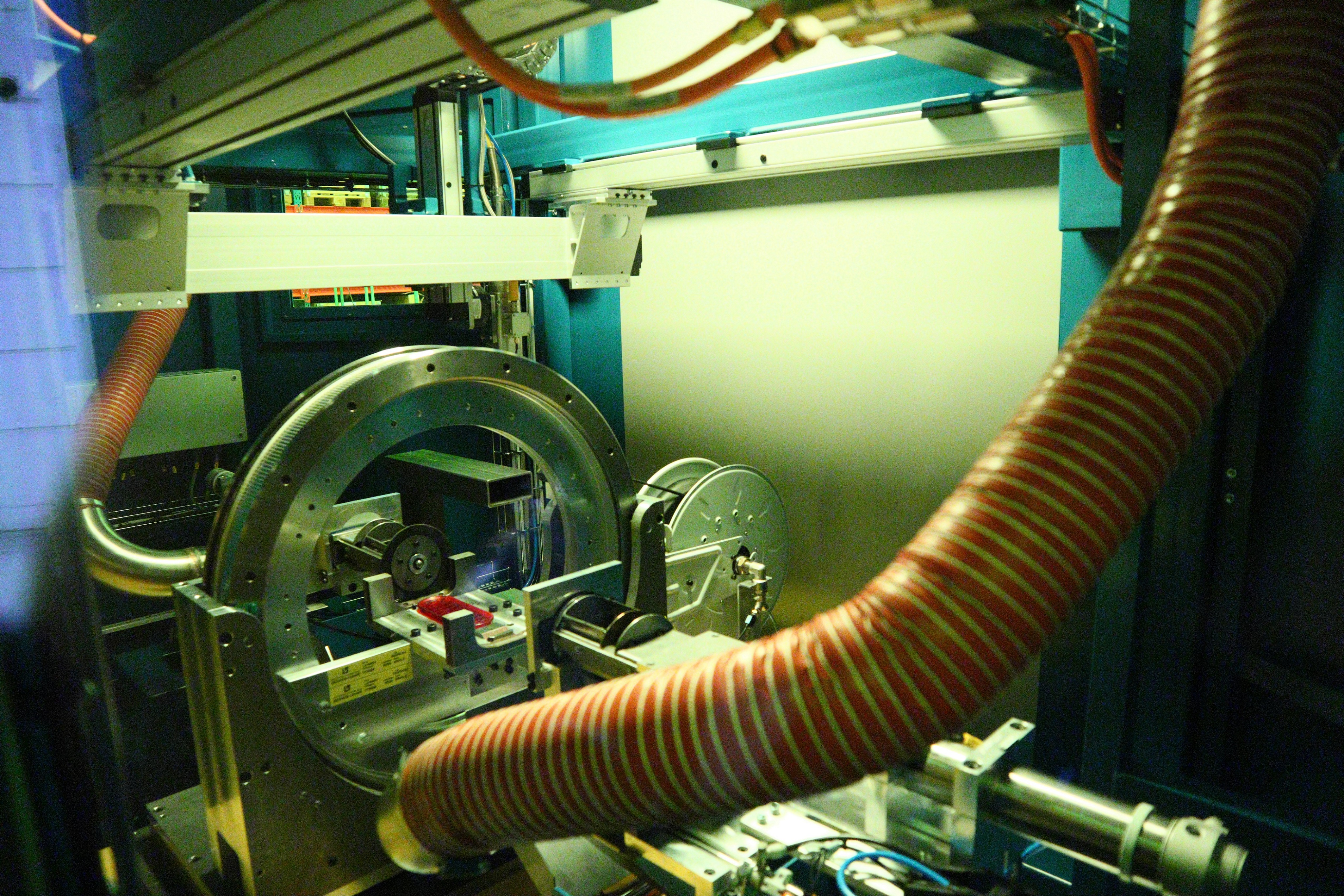

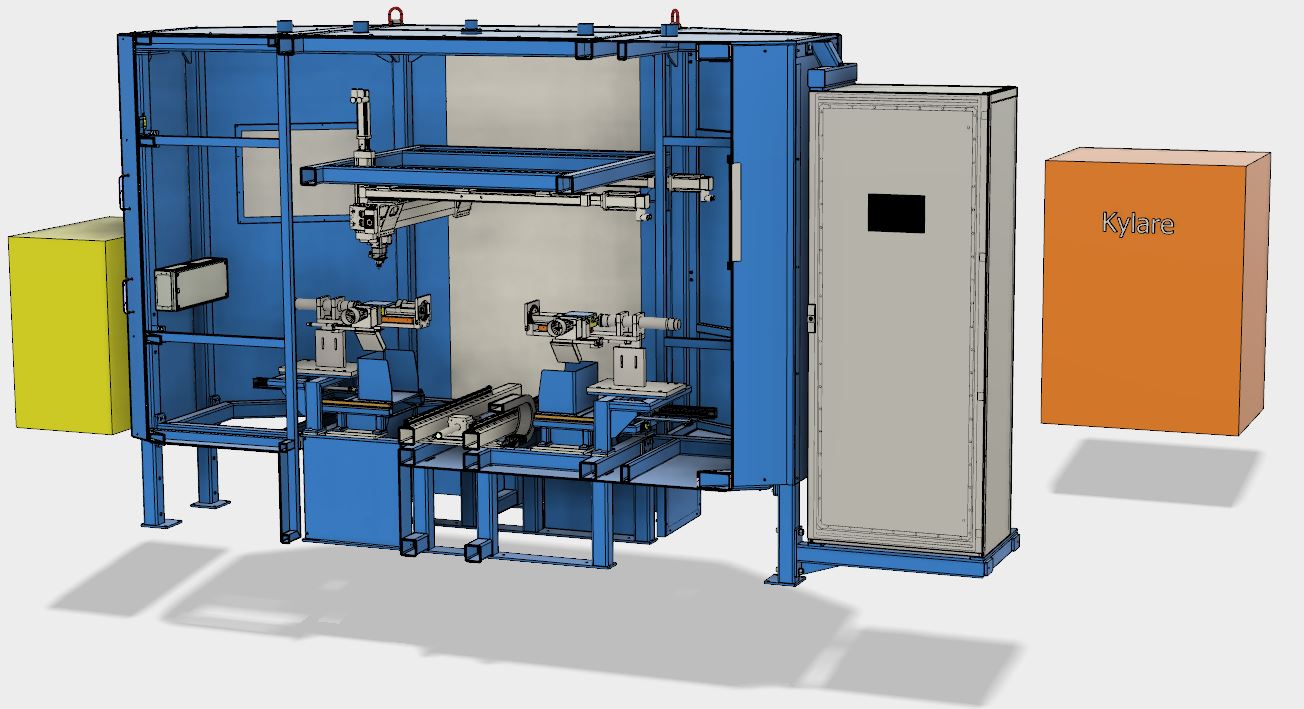

The machine was tasked with cutting holes at specific positions on all four sides of a square hydroformed pipe, then cut the collar of both sides of the pipe and put the resulting scrap in a bin for collection. The process had to be completely sealed in a light-proof, monitored Class 1 enclosure to ensure operator safety and cutting process control.

Together with our partner Maskinsystem AB, LMIAB built two of these systems. Today, they are both in full production.

” Process 1: Operator places the EGR-cooler material in a ring fixture. The material is locked in place using vacuum, and the operator starts the cycle by pushbutton. This feeds the table and fixture into the enclosure whereafter the front hatch closes. The laser head checks that the material is loaded correctly and begins laser cutting. When Process 1 cutting is finished, the front hatch opens and feeds the table and fixture out of the enclosure. The material is then moved to another machine for preparation before Process 2.

Process 2: The operator mounts a dowel in the fixture preventing the material from being mounted incorrectly. When the material is mounted and locked in place the table and fixture is again fed into the enclosure and the material is finally cut to the correct length. "