From rear mirrors to focusing lenses and every optical component in between.

We offer CO2 laser optics such as focusing lenses, parabolic mirrors, curved mirrors, collimators, reflective phase retarders, rear mirrors, output couplers and protective windows.

Among our suppliers are world-leading II-VI (Two Six) Infrared, which accounts for well over 80% of the world market for laser optics for CO2 lasers. Of course, we also have a number of other suppliers for everything from beam guide optics to beam guide components and protective windows for fiber lasers and other non-CO2 laser wavelengths.

Here are examples of different types of lenses:

- Cut Lenses

- MP-5 Ultra-low absorption for lasers with over 4 kW continuous power

- Aspherical Lenses

- Cylindrical Lenses

- Meniscus Lenses (Meniscus) the most common lens shape for the industry

- Plano Convex Lenses (PoCx)

Cleaning & Handling of CO2 Optics

Handling the laser optics is extremely important to ensure that it has the longest possible lifespan.

Quick tips for best results when cleaning ZnSe optics

Use acetone after an initial cleaning with acetic acid (20%, diluted with water) for best results. Acetic acid is available in most grocery stores. Acetone is also available in well-stocked grocery stores, we also have Acetone. It should be chemically pure (red label).

Do you have problems with, for example, the cutting results in your machine?

Then you should contact us and we can help you diagnose whether the fault lies in the optics or whether there is something in the process that is not working as it should. This service is free of charge, provided that you are a customer of ours of course. II'VI with its enormous experience and market leading position has both the equipment and resources to be able to analyze an old defective lens to see whether the fault lies in the optics or deeper down in the system.

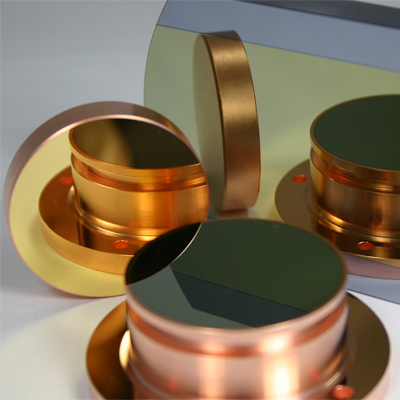

Mirrors - resonator optics

Mirrors are used in the beam path, where the laser beam is guided towards the cutting head in the laser machine, or in the resonator. The mirrors can be totally reflective or partially reflective depending on the purpose. In the resonator, a rear optic and a front optic, so-called output coupler, have been briefly described. In between, there can be several mirrors depending on the design of the resonator and how you want the beam to come out through the output mirror. The output mirror is always partially reflective, i.e. it lets through a certain proportion of the laser light that hits it and sends back a larger amount so that the amount of energy in the cavity is always maintained and a uniform flow radiates out of the resonator.