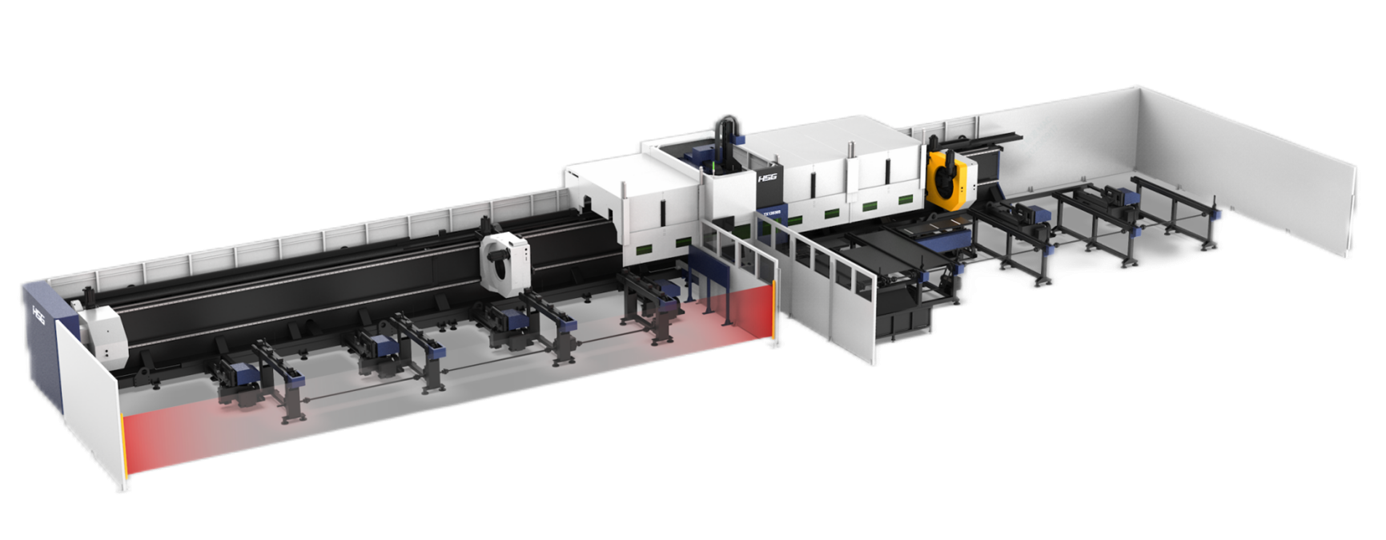

The HSG-TX is a powerful and specialized laser cutting machine for heavy processing of pipes and profiles in the rougher segment.

Ideal for companies that need to cut large and heavy materials, it offers high precision, efficient machining and advanced automation capabilities to optimize production.

Why HSG-TX laser cutting machine?

Developed with heavy industry in mind, the HSG-TX handles pipe lengths up to 12 meters, making it suitable for extensive processing of robust materials. The machine is equipped with HSG's patented 3+1 chuck, which not only provides stability, but also ensures that no material is wasted by minimizing the scrap length to 0 mm on a straight cut. For companies that require efficient and safe handling, TX also offers the option of integrating automation solutions for loading and unloading.

Features and benefits

HSG-TX offers high performance and precision with a powerful laser of 6,000 to 20,000 W and a rotation speed of 60 r/min. The machine can move at speeds up to 60 m/min without load and has an acceleration of 0.6G, which provides fast and efficient cuts. The positioning accuracy is ±0.05 mm/m, which makes it ideal for accurate machining of heavy materials.

One of the most unique features of the HSG-TX is its patented 3+1 chuck, which not only holds the material securely during cutting, but also automatically adjusts to straighten the tubes. This support eliminates the risk of residual scrap, contributing to material efficiency and less waste.

- Bevel cutting and versatile capacity

The machine has a bevel cutting capacity up to 45°, which makes it useful for complex cuts and simplifies subsequent welding work. The HSG-TX can handle a wide variety of material types and dimensions, from round tubes with a diameter of 40-360 mm to square tubes up to 250x250 mm, which provides great flexibility in production.

- Advanced automation and safety

To improve the workflow, the HSG-TX can be equipped with automation for both loading and unloading, as well as a height control system for safe material handling. The machine is also equipped with light curtains for extra safety and has an extensive parameter library to facilitate quick material setting. Autofocus and automatic altitude hold functions also increase accuracy and ease of use.

With the built-in nesting function, the TX can further optimize material utilization by arranging cutting paths for reduced waste. This, combined with the ability to save settings in the parameter library, makes it easy for the user to quickly adapt the cut for different materials and projects.

Summary

HSG-TX laser cutting machine is a robust tool for companies that need a reliable solution for heavy processing of pipes and profiles. With its advanced 3+1 chuck, high cutting precision and automation capabilities, the HSG-TX is an optimal choice to improve productivity and ensure efficient resource use in larger industrial projects.